|

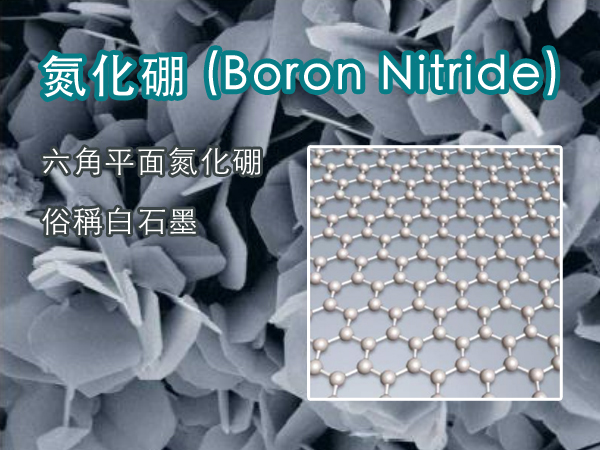

3M™ Boron Nitride Cooling Fillers |

Aluminum Oxide (Al2O3) |

| Raw Materials |

- Lower loading level

- Lower material consumption for thin-walled parts

|

- Requires higher filler loading to generate desired thermal conductivity

|

| Processing |

- Faster cycle times and line speeds

- Easier to process thin-walled and complex shapes

- No increase in wear on process tooling

- No dust build-up during processing

|

- Hard to process complex or thin-walled shapes

- Hard, abrasive particles cause wear on process tooling

|

| Final Article |

- Lighter weight, thinner parts

- High heat removal capability

- Simpler, more compact designs

- High reflectivity

|

- Higher density, heavier parts

- Low reflectivity for LED applications

|

| Property |

3M™ Boron Nitride Cooling Filler Platelets |

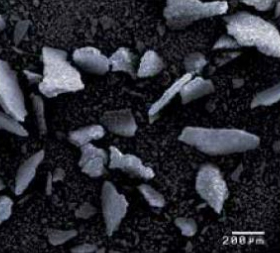

3M™ Boron Nitride Cooling Filler Flakes* |

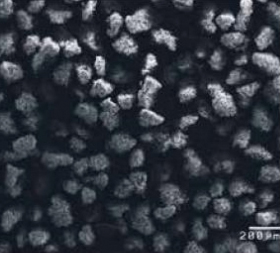

3M™ Boron Nitride Cooling Filler Agglomerates* |

| Form |

Highly crystalline BN single platelets |

Hybrid flake agglomerate of crystalline BN platelets |

Bulk agglomerate of crystalline BN platelets |

| Aspect Ratio |

|

Up to 30 |

1-2 |

| Particle Size (mean) |

1-15µm |

50-400µm |

20-400µm |

| Bulk Density (Scott) |

0.05-0.55 g/cm3 |

0.6-0.8 g/cm3 |

0.25-0.5 g/cm3 |

| Mohs hardness |

<2 |

| Electrical Resistance |

>1015 Ohm*cm |

| Dielectric Constant |

3.9 |

| Thermal Conductivity |

400 W/m*k (in-plane) |

| Applications |

Thermoplastic polymers |

Thermoplastic polymers, thermosets, resins |

Thermal interfaces (foils, pads, adhesives) |

|

|

|

|